PE filler masterbatch

PE Filler Masterbatch – the exclusive solution

PE Filler Masterbatch – the exclusive solution

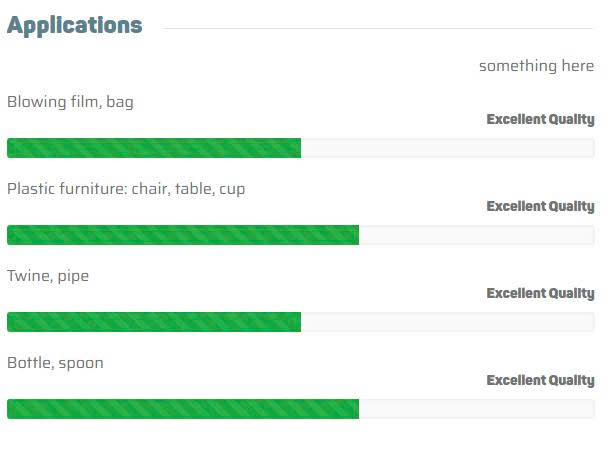

Our PE Filler Masterbatch benefits the characteristics of your products from enhancing the hardness, surface features chemical and physical durability and the elongation of the articles.

About Duc Huy’s PE Filler Masterbatch

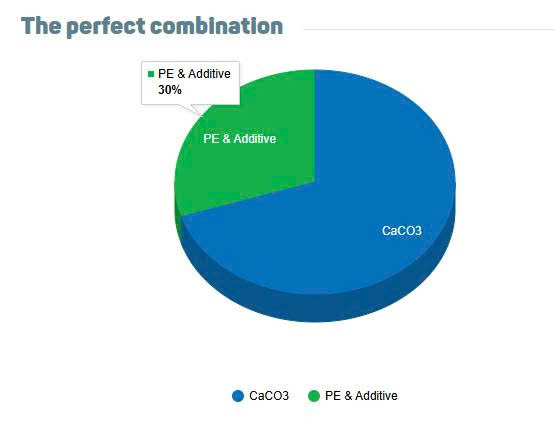

Our PE Filler Masterbatch is the perfect combination of fine pure calcium carbonate powder and appropriate additives in the polyethylene PE based masterbatch. In details, our most popupar PE Filler Masterbatch contains about 70% upto 80% fine pure CaCO3, 30% polyethylene PE and appropriate additives which depends solely on client’s requirements

PE Filler Masterbatch

- Improve anti-heating, rigidity and tightness property.

- Heightening the sub-light effect.

- Improve the surface antifriction and antislip property of plastic products.

- Reduce shrinkage ratio of final products to improve stability that size.

- Reduce fire heating quantity of plastic products second to reduce pollution.

- Heightening the plastic’s surface printing of plastic in order to eliminate electric current under surface corona process.

- Provide breathe free to film products.

- Improve heat-conduction property of plastic molding material to reduce period.

- Reduce the application ratio of white color masterbatch.

Packaging: Depend on the requirement of clients, we have two type of delivery

- 25 kgs per PE bag

- 1100kgs/jumbo bag

Delivering: Duc Huy delivers in 20 days. The delivery time will fit your processing needs after we made the final proforma invoice

Storage:

- The product is sensitive to moisture.

- No problem to store in original packing bags.

- Make sure to use the product immediately after open the packing bags. If it has moisture problem, Dry it by hot air recycle machine under 90°C for 30 minutes or give 1% desiccant masterbatch before using.

PE Filler Masterbatch – the exclusive solution

PE Filler Masterbatch – the exclusive solution