PP filler masterbatch

PP Filler Masterbatch – the exclusive solution

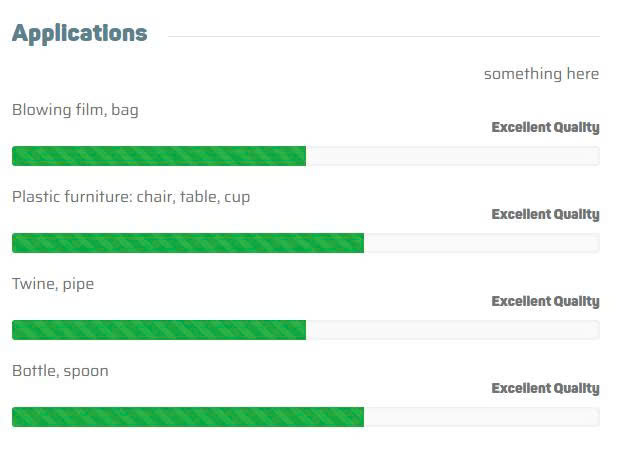

Duc Huy PP Filler Masterbatch contributes in optimizing the characteristic of plastic articles, enhancing flow properties with the durability, heat-resistant up to 300-celsius degree with excellent dispersion.

About Duc Huy’s PP Filler Masterbatch

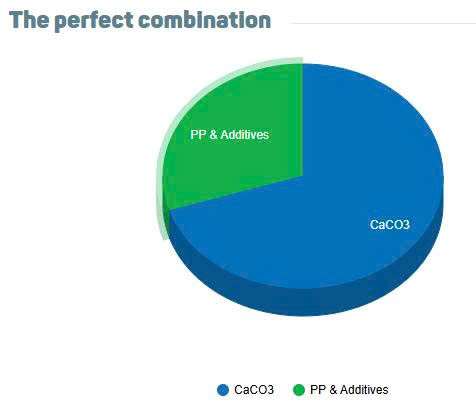

The combination of the most whiteness CaCO3 powder and polypropylene PP with other appropriate additives based on inquiries from clients. In general, the micro CaCO3 content takes roughly 70 to 80 percent of the total of PP composite masterbatch, the rests are polypropylene PP and other additives for handpicking properties to the final polymer products.

Packaging

There are two major types of PP filler masterbatch granules delivery bag with labeling depends on clients’ requirements, that our manufactory usually delivers as known as heavy-duty bag as follow:

- 25 kgs per PP bag

- 1100kgs/jumbo bag

Delivering

After handing out the final proforma invoice, we take assure that the delivery time will meet your processing needs. It might take 20 days for delivering as usual. Transportation of our PP filler masterbatch granules belongs to non-dangerous goods.

Storage

In order to maintain the properties of our plastic granules, please keep them in dry condition. Those plastic granules are sensitive to moisture, in the case, they have moisture problems, please dry them out by hot air recycle machine under 90-celsius degree into 30 minutes or give one percent desiccant masterbatch before making the use of them.

PP Filler Masterbatch

PP Filler Masterbatch